From Refrigerators to Gliders in 6 Months

Reprinted from a 1944 newspaper article

Playing tag with the clouds and taking free rides on the wind currents in a glider has been recognized for years as a fascinating and sporting adventure. Today, the glider is no longer merely the happy fun-craft of a few sportsman. It has swapped its gay colors for war paint, and has become a stealthy weapon of war. Gliders tell no tales of their approach. Fleets of them bearing men and guns on whispering wings can be towed over enemy lines while it is still dark, and released at high altitudes to swish down upon objectives at dawn. Protection by fighter and bombardment airplanes is provided the glider units during transit in theatres of operation and after they land. Since motor-power planes can pull three times as much as they can lift, gliders towed on cables can be used to haul more food and ammunition to our men in the front lines. They have been picked up from the ground by the Army Air Force's airplanes in full flight. The unprecedented expansion of the U. S. Army glider forces demanded that war gliders be placed into mass production. The Gibson Refrigerator Company was among the first of several prime contractors to produce gliders for the Air Corps. Other war materials, including bombs, precision testing apparatus for aircraft motors, delicate machinery for the polishing of lenses, and parts for anti-aircraft guns, are manufactured at their plant. But the outstanding Gibson war achievement to date has been their rapid change-over to the production of gliders after the refrigerator shutdown.

"From refrigerators to gliders in six months" has been Gibson's remarkable conversion record. When the change-over was begun, ninety percent of the Gibson engineering staff went to work on the gliders. Speaking of his company's speedy conversion to war glider manufacture, Charles J. Gibson president, says: “. . . Conversion to glider production was not so easy. A large portion of a glider is made of wood, and since we had years ago dispensed with wood in refrigerator production, it was not a simple process to return to it. But with the Government's help in securing woodworking machinery, plus the experience of old-time ice refrigerator workmen who have been with us for many ears, we were able to produce all wood parts for our first glider in our own factories, with the exception of only one assembly which we subcontracted." To provide the large open spaces required for the manufacture of aircraft, three large warehouses, formerly housing raw material and finished refrigerator and electric range stocks, were cleared. One warehouse is devoted to metal assembly, another to wood assembly of component parts of the glider and the third to final assembly of the entire glider. When used as warehouses, these buildings naturally were not heated. Before workers could start turning out gliders at top speed, comfortable temperatures had to be supplied. Into the warehouses rolled a quantity of round heating units---Trane Projection Heaters. These units were spaced at regular intervals at the ceiling of the long, wooden buildings. The wood used in the construction of gliders must be properly seasoned and processed before it can take its place on the completed ship. Lumber must be thoroughly dried to prevent warpage and shrinking.

In the warehouse where actual fabrication and assembly of wood parts are completed, a considerable amount of lumber is stored for immediate use. Here, high humidity conditions must be maintained for two reasons. In the first place, correct humidity conditions improve the workability of the wood parts in the manufacture of the glider assemblies. In addition, high humidity must be maintained to prevent the surface of the stored lumber from drying more rapidly than the interior. Conditions of 72° Dry Bulb and 5.5 % Relative Humidity are maintained by means of a complete system consisting of Trane Heating Coils, a Trane Spray Type Climate Changer and a Trane Blower Fan. The Climate Changer contains no coils and serves only as a spray humidifier. One bank of heating coils preheats the outside air while a second bank located beyond the humidifier serves a reheat purpose. In the spray dope building, proper ventilation is required because of the explosive nature of the operation involved. There, three Trane Blower Type Unit Heaters with face and by-pass dampers, filter section and mixing chambers are installed. This equipment is explosion proof. Pneumatic automatic controls allow the rise of 100% fresh air by either one, two or three units. The Trane Units in the spray dope building were installed by the Grand Rapids Blow Pipe and Dust Arrester Company to serve in conjunction with their spray booth units. The Trane Products have handled the temperature situation in a masterful manner, as is evidenced by this declaration of an official of the Gibson Company: "Since this conversion was made and the Trane units installed, the 'climate' in these warehouses is perfect, and . . . has a highly beneficial effect on both materials used and the men who are engaged in fitting the materials together."

Glider Specs

GENERAL SPECIFICATION - CG4A

Wing Span: 83 feet, 8 inches

Length (Overall): 48 feet, 33/4 inches

Height: 12 feet, 77/16 inches

Weight, design: 3,750 pounds

Gross Weight, design : 7,500 pounds

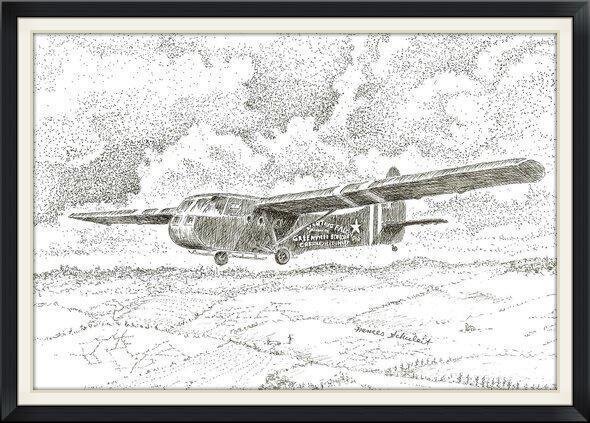

Wing Chord:10 feet, 6inches

The CG4A was not designed to be a thing of beauty, and certainly it was not considered to be an attractive aircraft. Most Air Force power pilots joked about its ungainly appearance but few of them poked any funny remarks at the guys who flew them. The glider pilots were an independent, tough, ready-to-fight group of pilots and they certainly were not backward in letting anyone know that the "G" on their silver wings stood for "Guts." The aircraft they flew with such abandon and ease was a strut-braced high-wing monoplane that could carry more than its own weight in payload, and frequently did.

The wing, constructed around a front box spar and a rear "I" spar, had wooden ribs, and was plywood-covered except for the trailing edge. The whole was covered with doped cotton fabric. The control surfaces were fabric covered except for the leading edges which were of plywood. The wing tips were elliptical and there was little dihedral. The fuselage was a welded steel tubing frame covered with fabric. The floor of the cargo compartment was of honeycombed plywood construction and had tremendous strength and rigidity. The cockpit was constructed also of a welded steel tubing frame covered with fabric and plywood.